![]()

TTS-IS6 Full Contact Internal Floating Roof Seal System

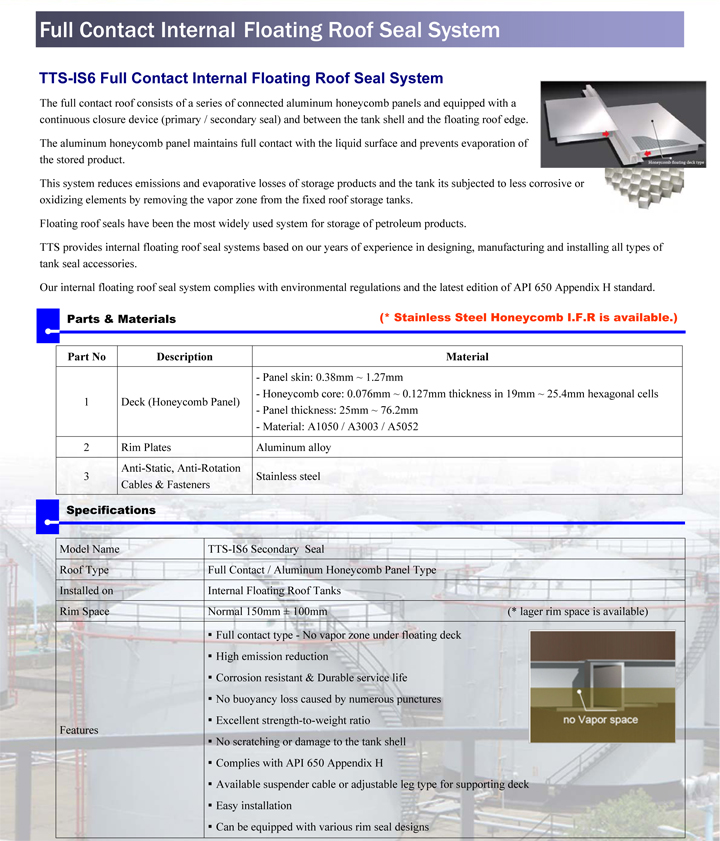

The full contact roof consists of a series of connected aluminum honeycomb panels and equipped with a continuous closure device (primary / secondary seal) and between the tank shell and the floating roof edge. The aluminum honeycomb panel maintains full contact with the liquid surface and prevents evaporation of the stored product. This system reduces emissions and evaporative losses of storage products and the tank its subjected to less corrosive or oxidizing elements by removing the vapor zone from the fixed roof storage tanks. Floating roof seals have been the most widely used system for storage of petroleum products. TTS provides internal floating roof seal systems based on our years of experience in designing, manufacturing and installing all types of tank seal accessories. Our internal floating roof seal system complies with environmental regulations and the latest edition of API 650 Appendix H standard.

Parts & Materials (*Stainless Steel Honeycomb I.F.R is available.)

| Part No | Description | Material |

| 1 | Deck (Honeycomb Panel) |

|

| 2 | Rim Plates | Aluminum alloy |

| 3 | Anti-Static, Anti-Rotation Cables & Fasteners |

Stainless steel |

Specifications

| Model Name | TTS-IS6 Secondary Seal |

| Roof Type | Full Contact / Aluminum Honeycomb Panel Type |

| Installed on | Internal Floating Roof Tanks |

| Rim Space | Normal 150mm ± 100mm (* lager rim space is available) |

| Features | ▪ Full contact type – No vapor zone under floating deck ▪ High emission reduction ▪ Corrosion resistant & Durable service life ▪ No buoyancy loss caused by numerous punctures ▪ Excellent strength-to-weight ratio ▪ No scratching or damage to the tank shell ▪ Complies with API 650 Appendix H ▪ Available suspender cable or adjustable leg type for supporting deck ▪ Easy installation ▪ Can be equipped with various rim seal designs |

| Item | TTS Internal Floating Roof |

| Pontoon | Floating Tube Type, Aluminum or Stainless Steel |

| Deck Skin | Aluminum or Stainless Steel |

| Rim Space | Normal 180mm ± 100mm (* larger rim space is available) |

| Type of Seals | ▪ Primary Seal: Wiper Seal, Liquid Mounted Foam Seal or Mechanical Seal ▪ Secondary Seal: Wiper Seal |

| Advantages | ▪ Reduce product evaporation loss ▪ Reduce potential for vapor space explosions and fire harzards ▪ Preserve the environment ▪ Better peripheral sealing and lower seal cost ▪ Cost effective initial investment ▪ Long service life ▪ No normal maintenance requirement ▪ 100% aromatic protection available ▪ Complies with API 650 Appendix H standard ▪ Compatible with all stored products: Crude oil, Naphtha ▪ Designed to access all components through the manhole |

The wiper seals mounted above each other that completely cover the space between the tank shell and the edge of the internal floating roof. The wiper seal is continuous and both wiper seals are vapor mounted type. The wiper seal is made from high quality material which has 100% aromatic resistance. Double wiper seals are easy to install and have a low cost.

The primary seal is liquid mounted type which is composed of foam and envelope and the secondary wiper seal is vapor mounted type. The envelope is designed to prevent liquid capillary action and provide a long service life for B.T.X and other strong chemical storage tanks. This foam seal can effectively reduce VOC emissions and project losses of liquid product completely.

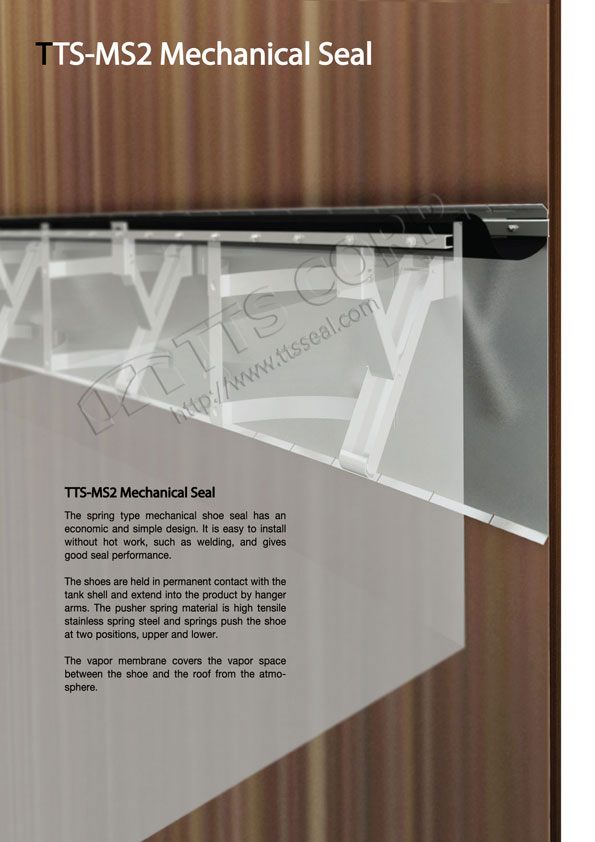

The mechanical shoe seal is a metal sheet held vertically against the wall of the storage tank by springs and is connected by brace arms to the floating roof. A flexible coated fabric (continuous seal) spans the annular space between the shoe plate and the rim plate of the floating roof. This seal offers virtually universal resistance to all storage products, good emission reduction, long service life and liquid mounted advantages.

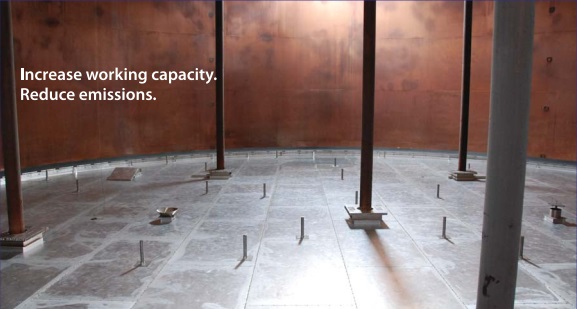

The full contact floating roof consists of a series of connected aluminum honeycomb panels and equipped with a continuous closure device (primary / secondary seal) and in-between the tank shell and the floating roof edge.

The aluminum honeycomb panel maintains full contact with the liquid surface and prevents evaporation of the stored product.

This system reduces emissions and evaporative losses of storage products and the tank its subjected to less corrosive or oxidizing elements by removing the vapor zone from the fixed roof storage tanks.

Specifications

| Roof Type | Full Contact / Aluminum Honeycomb Panel Type (Stainless Steel is available) |

| Installed on | Internal Floating Roof Tanks |

| Rim Space | Normal 150mm ± 100mm (larger rim space is available) |

| Features |

|

The panto graph type mechanical shoe seal is the most widely used design on external floating roof tank and provides long service life. The metallic band is formed as a series of shoes that are overlapped together to form a ring and held against the tank shell by panto graph type mechanical device. The counterweight assembly and arm exerts a constant pressure to push the shoe against the tank shell. The continuous seal covers the vapor space between the shoe and roof from the atmosphere.

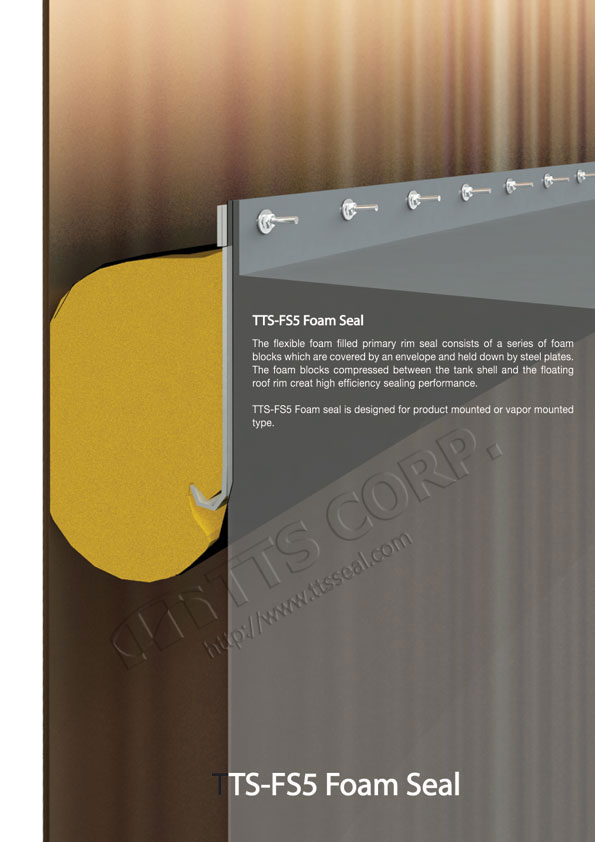

The flexible foam filled primary rim seal consists of a series of foam blocks which are covered by an envelope and held down by steel plates. The foam blocks compressed between the tank shell and the floating roof rim effect high efficiency sealing performance.

TTS-FS5 Foam Seal is designed for product mounted or vapor mounted type.

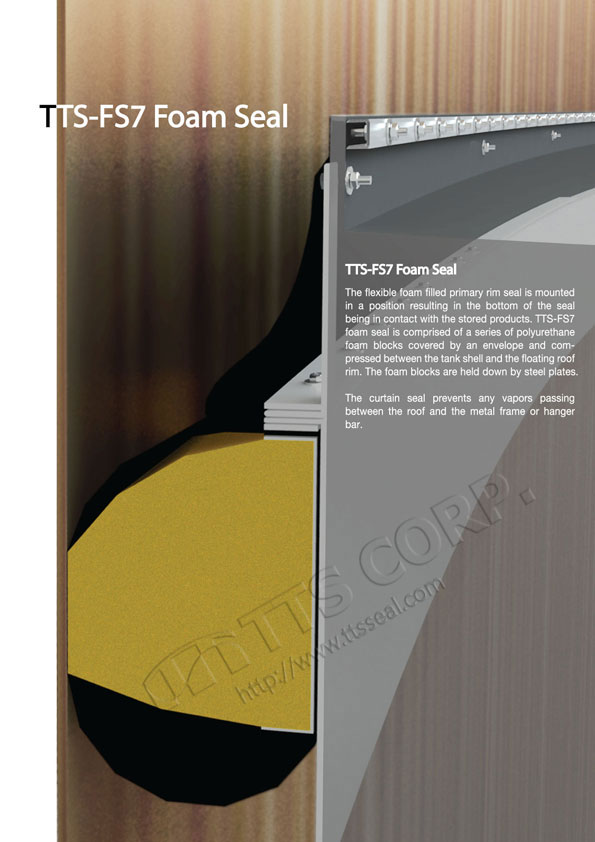

The flexible foam filled primary rim seal is mounted in a position resulting in the bottom of the seal being in contact with the stored products. TTS-FS7 Foam Seal is comprised of a series of polyurethane foam blocks covered by an envelope and compressed between the tank shell and the floating roof rim. The foam blocks are held down by steel plates. This product mounted type eliminate vapor area.

The curtain seal prevents any vapor passing between the roof and the metal frame or hanger bar.

The flexible foam filled primary rim seal consists of a series of foam block which are covered by an envelope and held down by steel plates. The foam blocks compressed between the tank shell and the floating roof rim effect high efficiency sealing performance.

TTS-FS8 Foam Seal is designed for product mounted or vapor mounted type.

The tube containing compatible liquid is covered by a scuff band and located directly on the stored product. The liquid filled tube gives pressure softly to the tank shell and eliminates the space between the stored product and seal. Against the tank shell is a scuff band of nylon fabric coated with an abrasion resistant polymer coating which prevents a ribbed surface to the shell. The scuff band is attached at top and bottom by bolting in such a fashion that the lower portion of the scuff band is in contact with the stored liquid, i.e., product mounted.

The filled tube exerts a hydraulic pressure outwards holding the scuff band against the tank shell and so effecting a seal.

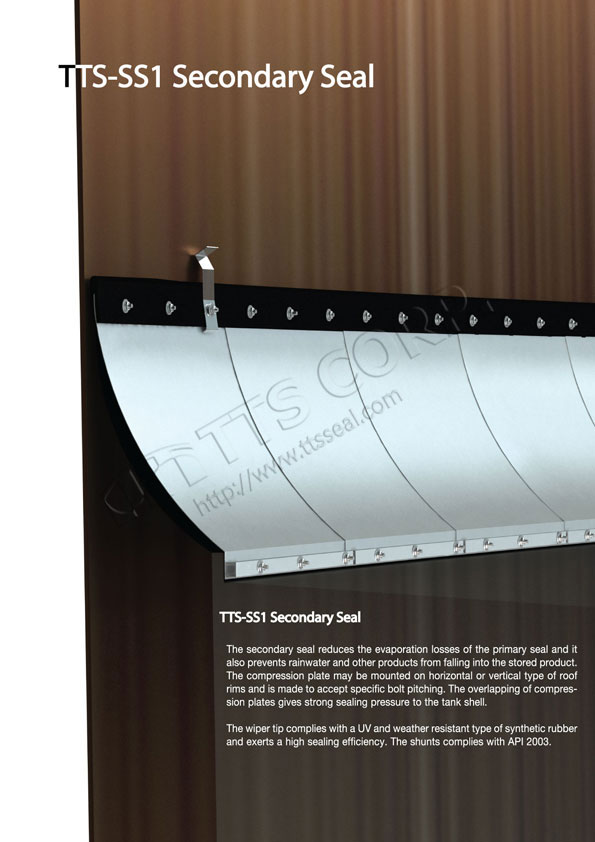

The secondary seal reduces the evaporation losses of the primary seal and it also prevents the rainwater and other products from falling into the stored product. The compression plate may be mounted on horizontal or vertical type of roof rims and is made to accept specific bolt pitching. The overlapping of compression plates gives strong sealing pressure to the tank shell. The wiper tip complies with a UV and weather resistant type of synthetic rubber and exerts a high sealing efficiency. TTS-SS1 is available to re-entry the tank without any damage and hang up when over filled. The shunts complies with API 2003.

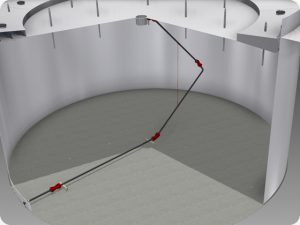

The roof drain system is equipped to remove the accumulated rain-water from the topside of the external floating roof tanks. The articulated rigid pipe type roof drain system is composed of swivel joints and rigid steel pipes. The swivel joint is high quality and it assures a long life service. This roof drain system has 100% aromatic resistance.

Parts & Materials

| Part No | Description | Material |

| 1 | Pivot Joint | S.S Hose w/ Hot Dip. Galv. Guide Plate |

| 2 | Drain Pipe | Carbon steel |

| 3 | Stop Chain | Hot Dip Galv. Steel |

| 4 | Pipe Support | Carbon steel |

| 5 | Check Valve | Carbon steel (*optional) |

Specifications

| Model Name | TTS-RD2, Roof Drain System |

| Type | Pivot Joint Type w/ Rigid Pipes |

| Installed on | External Floating Roof Tanks |

| Available Size | 3” ~ 6” |

| Features | ▪ Compatbilitywith wide ragnge of produt ▪ No o-rings, seals and bearings ▪ No lubrication requird ▪ No stress or load on hose end connection ▪ Drain line doesn’t scrape or drag on the tank bottom ▪ Does not add pressure to the floating roof. ▪ High operating presure ▪ Has negative buoyancy in water or heavy crude. ▪ Less maintenance. ▪ Long service life ▪ Easy to install |

The roof drain systems is equipped to remove the accumulated rainwater from the topside of the external floating roof tanks. The simply hose attaches a flange located near the center of the roof and a flange at the base of the tank. Flexible hose type roof drain systems have no intermediated joints.

Types and Specification

| Stainless Steel Armored Hose | Flexible Hose |

| ● Stainless steel armored cover ● Full-flow, compression-sealed end fittings ● Available size: 3”, 4”, 6” & 8” |

● Nylon protective scuff-jacket ● Installed with support saddle, chain and clevis ● Can be installed as one-continuous length — center sump to shell ● Available size: 3”, 4”, 6” & 8” |

Features

- Operates in a vertical plan and does not scrape on the floor of the tank.

- Proprietary desinged fittings give roof drain permanent non-leaking couplings at ecch end of the assembly.

- Does not add pressure to the floating roof.

- Won’t cause ‘off-center” roof or seal gaps such as those caused by swivel joints or hard piped systems.

- Has negative buoyancy in water or heavy crude.

- Less maintenance.

- Long service life.

- Easy to install.

Articulated Rigid Pipe Type Floating Suction System

Aviation fuel, heating oils, petrochemicals and water need to be delivered without impurities. TTS Floatig Suction System is used to deliver a clean product from a defined depth under the liquid level.The highly qualified swivel joint assures a durable serice life and performance. The float tubes are all pressure tested.

Articulated Rigid Pipe Type Oil Skimmer System

TTS Oil Skimmer System is used to extract the top layer of liquid or skin off impurities usually a layer of light oil. The highly qualified swivel joint assures a durable service life and performance. The float tubes are all pressure-tested. There is a minimum vortex formation using an anti-vortex inlet.

The aluminum dome is designed as a self-supporting, clear-span and fully triangulated structure and only its outer edge is connected to the tank shell around the outer rim. The Aluminum domes are generally constructed according API 650 appendix G, the standard setting details for aluminum domes on storage tanks in refineries. They are also ideal for bulk storage, potable water, waste water and architectural structures.

Features

- Lightweight

- Self-supporting structure

- All Aluminum Construction

- Corrosion Resistant

- Low Maintenance

- Emissions reduction

- In-Service Installation

- Quick Field Installation

- Water- tight protection

Advantages

- Keep rain, sand, and snow from entering the tank to protect storage product.

- Result in an important reduction of evaporation loss.

- Offer a cost-effective solution by saving the weight of the tank cover like steel roof.

- Fabricate from highly-tensile aluminum alloys and possess excellent corrosion resistant, especially in a humid or saline atmosphere.

- Design Fixed /sliding for dome support.

- Prefabricate all parts to be quick field installation.

- Meet the customer’s request to provide a wide range of accessories such as vents, skylight, walkway, center platform, gauge hatch, etc.

Flame Arrester

The flame arrester is a device to the opening of an enclosure or to the connection pipe work of a system of enclosure and whose intended function is to allow gas flow but prevent the transmission of flame propagation. The frame arresters can be used to prevent flame propagation in the presence of explosive atmospheres, e.g. though piping, breathers and filling and emptying lines that are nor full of liquid at all times.

Breather Valve (Pressure and/or Vacuum Relief Valve)

The breather valve are designed to protect ASTs from the excessive pressure and/or vacuum. When a tank is being filled, the vapor that filled the space above the liquid surface is compressed and it this pressure were allowed toexceed the storage tank design pressure, then it would explode or rupture. In addition, if the temperature of the storage tank or vessel increases, then expansion and vaporization may cause the pressure to rise.

Conversely, emptying liquid from the tank, or a decrease of temperature, cause a vacuum to be created.

Emergency Vent

The emergency vent cover is designed to provide emergency relief capacity beyond that furnished by the normal operating pressure & vacuum relief valve on the tank. These large relief cover which only open in emergencies are used to protect tanks against rupture or explosion that could result from thermal pressure caused by fire surrounding a tank, etc. It remains closed tightly at all internal pressure below setting pressure (and above the vacuum setting). These cover also provides easy access into the tank.

Gauge Hatch Cover

Gauge hatch designed to provide easy access to storage tanks for checking level of temperature of products, and for sampling. It is available either with or without a cover clamp. The hatch cover without the clamp can by used as emergency pressure venting up to 3 psig of pressure.

Gauge Pole Covers are an innovative solution to emission reductions in Floating Roof Tanks. It is designed to inhibit hydrocarbons from escaping through slots in slotted holes from dip pipes.

Features

- Reduces product emissions and save the vapor loss

- Meets the environmental regulations

- Can be installed while tank remains in service

- Freely use gauging and sampling equipment

- Chemical resistance and UV protection

- Folding cover design provides flexibility

- Hook/Zipper/Linking tape triple connection for easy installation

- Easily lowers for use of the ladder

- Custom design to ensure effective operation

- Provides efficient and economical solution

Features

- Gauge pole: 2”, 3”, 6”, 8”, 10” or upon request

- Ladder: design upon the ladder size and tank height

- Cover material: Polyurethane Coated or upon request

- Metal parts: Stainless steel or upon request

- Coil size: Ø3mm or upon request