TTS-IS6 Full Contact Internal Floating Roof Seal System

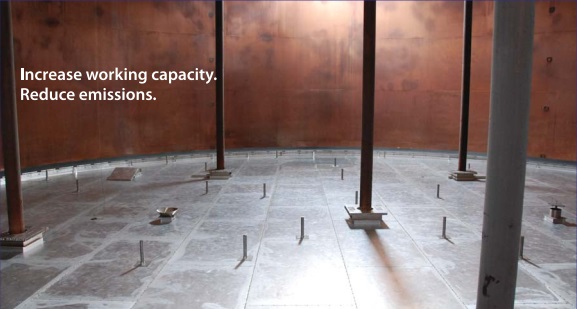

The full contact roof consists of a series of connected aluminum honeycomb panels and equipped with a continuous closure device (primary / secondary seal) and between the tank shell and the floating roof edge. The aluminum honeycomb panel maintains full contact with the liquid surface and prevents evaporation of the stored product. This system reduces emissions and evaporative losses of storage products and the tank its subjected to less corrosive or oxidizing elements by removing the vapor zone from the fixed roof storage tanks. Floating roof seals have been the most widely used system for storage of petroleum products. TTS provides internal floating roof seal systems based on our years of experience in designing, manufacturing and installing all types of tank seal accessories. Our internal floating roof seal system complies with environmental regulations and the latest edition of API 650 Appendix H standard.

Parts & Materials (*Stainless Steel Honeycomb I.F.R is available.)

| Part No | Description | Material |

| 1 | Deck (Honeycomb Panel) |

|

| 2 | Rim Plates | Aluminum alloy |

| 3 | Anti-Static, Anti-Rotation Cables & Fasteners |

Stainless steel |

Specifications

| Model Name | TTS-IS6 Secondary Seal |

| Roof Type | Full Contact / Aluminum Honeycomb Panel Type |

| Installed on | Internal Floating Roof Tanks |

| Rim Space | Normal 150mm ± 100mm (* lager rim space is available) |

| Features | ▪ Full contact type – No vapor zone under floating deck ▪ High emission reduction ▪ Corrosion resistant & Durable service life ▪ No buoyancy loss caused by numerous punctures ▪ Excellent strength-to-weight ratio ▪ No scratching or damage to the tank shell ▪ Complies with API 650 Appendix H ▪ Available suspender cable or adjustable leg type for supporting deck ▪ Easy installation ▪ Can be equipped with various rim seal designs |

| Item | TTS Internal Floating Roof |

| Pontoon | Floating Tube Type, Aluminum or Stainless Steel |

| Deck Skin | Aluminum or Stainless Steel |

| Rim Space | Normal 180mm ± 100mm (* larger rim space is available) |

| Type of Seals | ▪ Primary Seal: Wiper Seal, Liquid Mounted Foam Seal or Mechanical Seal ▪ Secondary Seal: Wiper Seal |

| Advantages | ▪ Reduce product evaporation loss ▪ Reduce potential for vapor space explosions and fire harzards ▪ Preserve the environment ▪ Better peripheral sealing and lower seal cost ▪ Cost effective initial investment ▪ Long service life ▪ No normal maintenance requirement ▪ 100% aromatic protection available ▪ Complies with API 650 Appendix H standard ▪ Compatible with all stored products: Crude oil, Naphtha ▪ Designed to access all components through the manhole |

The wiper seals mounted above each other that completely cover the space between the tank shell and the edge of the internal floating roof. The wiper seal is continuous and both wiper seals are vapor mounted type. The wiper seal is made from high quality material which has 100% aromatic resistance. Double wiper seals are easy to install and have a low cost.

The primary seal is liquid mounted type which is composed of foam and envelope and the secondary wiper seal is vapor mounted type. The envelope is designed to prevent liquid capillary action and provide a long service life for B.T.X and other strong chemical storage tanks. This foam seal can effectively reduce VOC emissions and project losses of liquid product completely.

The mechanical shoe seal is a metal sheet held vertically against the wall of the storage tank by springs and is connected by brace arms to the floating roof. A flexible coated fabric (continuous seal) spans the annular space between the shoe plate and the rim plate of the floating roof. This seal offers virtually universal resistance to all storage products, good emission reduction, long service life and liquid mounted advantages.

The full contact floating roof consists of a series of connected aluminum honeycomb panels and equipped with a continuous closure device (primary / secondary seal) and in-between the tank shell and the floating roof edge.

The aluminum honeycomb panel maintains full contact with the liquid surface and prevents evaporation of the stored product.

This system reduces emissions and evaporative losses of storage products and the tank its subjected to less corrosive or oxidizing elements by removing the vapor zone from the fixed roof storage tanks.

Specifications

| Roof Type | Full Contact / Aluminum Honeycomb Panel Type (Stainless Steel is available) |

| Installed on | Internal Floating Roof Tanks |

| Rim Space | Normal 150mm ± 100mm (larger rim space is available) |

| Features |

|